Portal reclaimer

Keywords:

Heavy machinery | Power station auxiliary equipment | Engineering general contracting | Mining machinery | Environmental protection equipment

Category:

Service hotline:

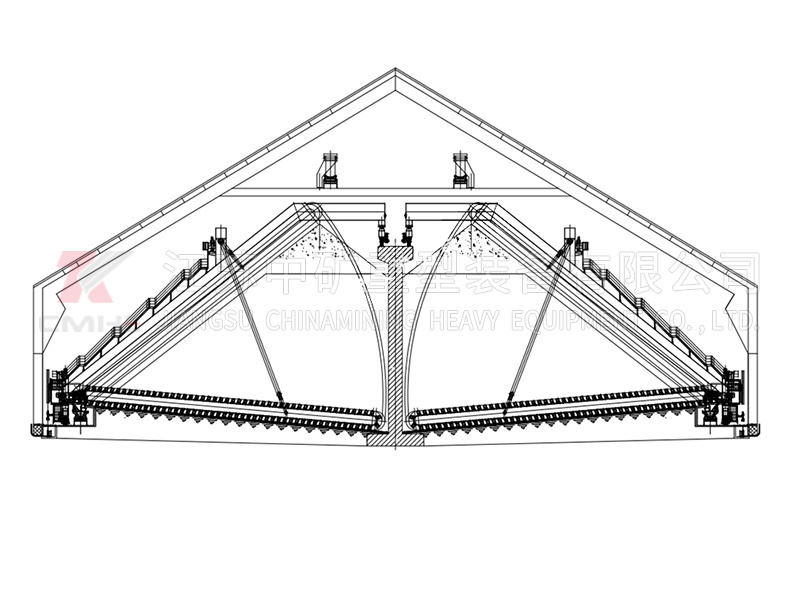

Portal reclaimer

The mechanism of portal reclaimer is connected by the portal metal main frame mechanism. This series of machines can carry out high and low stacking operations across material piles, and have a certain mixing effect. According to the user's requirements, the tail car can realize the functions of straight passing, picking up and sending back, shunting and stacking.

Basic structure of portal reclaimer

It is composed of the following mechanisms: portal frame, fixed beam, movable beam, movable beam lifting mechanism, single-beam crane, bucket wheel, reclaiming belt conveyor.

Conveyor, stacking belt conveyor, mobile belt conveyor, mobile belt conveyor streamer, lifting mechanism, traveling mechanism, anchorage and rail clamping device, crane traveling detection device, drum mechanism, drum mechanism streamer, counterweight mechanism, passing tail car, stacking coal hopper of tail car and coal baffle, coal hopper of tail car, electrical room of stacking displacement mechanism of tail car, electrical system, power cable drum and control cable drum.

The portal reclaimer has a lifting bridge called a movable beam. The irregular bucket wheel is installed on the movable beam. The bucket wheel is installed on the trolley that can run along the movable beam by means of the round raceway, the support wheel and the stop wheel. With this kind of trolley, the bucket wheel can move along the movable beam and can reach any horizontal position for excavation.

The longitudinal movement of the bucket wheel depends on the traveling of the crane. A belt conveyor is installed on the movable beam. The height of movable beam can be adjusted up and down by winch or hydraulic cylinder to adapt to different pile heights during excavation.

The tail car running with the gantry is set on the belt conveyor line of the storage yard at the side of the gantry. There are two ways to change the loading and unloading of the tail truck. One way is to change the position of the front part of the tail car relative to the movable beam through the ring installed at one end of the movable beam, and the other way is to change the position of the tail car relative to the movable beam through its own or electric push rod. When the height of the movable beam changes, the front part of the tail car moves with the movable beam.

The belt conveyor of the gantry reclaimer has three types of layout: three belt conveyors are in the movable beam, two of which are used for stacking, and all three are used for reclaiming; The conveyor belt in the movable beam is used for reclaiming, and the conveyor belt in the lower part of the main beam is used for stacking; There is a conveyor belt in the movable beam, which can be used for stacking and reclaiming. The installation forms of bucket wheel stacker and reclaimer are left and right respectively.

Technical Parameters

|

production capacity |

100-2500 |

t/h |

||

|

Material characteristics |

Bulk density of the material |

0.35-2.4 |

t/m³ |

|

|

granularity |

≤300mm |

mm |

||

|

Yard parameters |

Straight gauge |

18-65 |

m |

|

|

Walking speed |

Reclaiming runs frequency conversion |

0.5-2 |

m/min |

|

|

Shunting operation frequency conversion |

2-15 |

m/min |

||

|

Reclaiming method |

Scraper |

|||

|

Structural form |

Gantry type |

|||

|

Luffing form |

Mechanical winches |

|||

|

Control mode |

Manual, automatic |

|||

|

Power supply |

Power supply mode |

Moving cable drum |

||

|

Electric |

AC, three-phase four-wire, 380 volts, 50 Hz |

|||

More Products

Product Consultation

Website

Service hotline

Business Department:

Zhou Baohua 86-13906278080

Technical support:

Ding Baoqin 86-13906276368

Fax: 86-513-88400998

E_ mail: jszk@vip.163.com

Address: No. 29 Xingdian West Road, Baidian Town, Hai'an City, Jiangsu Province