Clinker bulk machine

Keywords:

Heavy machinery | Power station auxiliary equipment | Engineering general contracting | Mining machinery | Environmental protection equipment

Category:

Service hotline:

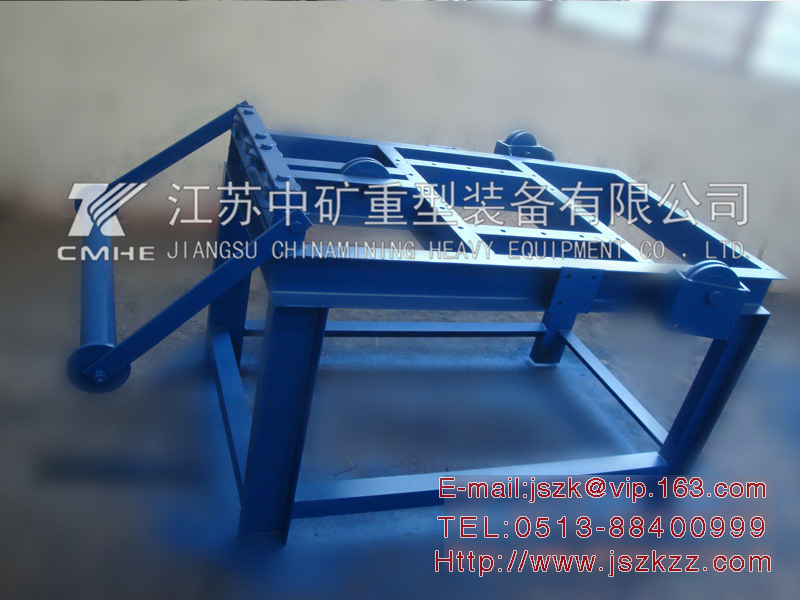

Clinker bulk machine

Clinker bulk loader produced by Jiangsu ChinaMining is a device that automatically transports clinker (≤ 50mm) from the warehouse to the clinker bulk carrier. The bulk equipment for cement clinker at the bottom of the warehouse mainly consists of manual rod valves, electric fan valves, winch devices, telescopic discharge devices, dust collection hoses, capacitive limit switches, electrical control systems and other components. Users can also choose the warehouse side clinker bulk equipment.

Ⅱ. Technical parameter table

|

Technical performance |

Technical Parameter |

|

Conveying materials |

Cement clinker or similar block materials |

|

Material bulk density |

clinker 1.45t/m3 |

|

Material temperature |

<=80℃ |

|

Material particle size |

<=50(mm) |

|

Loading capacity |

200t/h |

|

Expansion and contraction distance of discharge head |

Customized according to user requirements |

|

Manual rod valve |

790x790mm 410x410mm |

|

Electric sector valve |

DZG1103 2x1.1KW |

|

Pneumatic rod valve |

DTY700-400/100 1.5KW(气缸cylinder:QGB125x400-MP4) |

|

Winch |

CD1-18D Power:3KW lifting speed:8m/s |

|

Capacitive limit switch |

FTC131Probe specifications:Probe diameter ф25x400 Working pressure 10baroperation temperature -20℃-80℃ FTM131Probe specifications:Probe diameter ф20x230 lengthening 170mmWorking pressure 10bar |

|

Installed power |

~5.2Kw~4.5Kw(~3KW) |

|

Reference drawing |

SZT300-Ⅰ/1、SZT300-Ⅱ/2、SSQ300-Ⅲ |

|

Model |

Warehouse bottom, warehouse bottom, warehouse side |

:

Ⅲ. Working principle

After the transportation carrier enters the position, open the corresponding bars of rod valves. Press and hold the "lowering button" on the control cabinet. Once the feeding head is in place, the power supply of the lifting motor will be automatically disconnected. Press the "loading button" to enter the feeding state, and the auxiliary equipment will start working accordingly. The dust generated during unloading will pass through the feeding hopper and enter the dust collector for purification through the telescopic dust collection hose. When the material in the lower feeding head is full, the feeding head will raise while giving an alarm, and the rising distance should be set before loading. If the rise distance is 1 meter, adjust the time of the time relay to T=1/V. During the rising process, the loading process is always ongoing. When the current material head is full, repeat the above action. After reaching the full material position, press the stop button to reverse the brake of the electric vibration machine, or close the fan-shaped valve to stop feeding, and other equipment will stop working accordingly. After parking, press the up button to keep the lower hopper away from the material, ensuring the movement of the transportation tool, and then align it with the unloading station until the entire storage bin is filled.

More Products

Product Consultation

Website

Service hotline

Business Department:

Zhou Baohua 86-13906278080

Technical support:

Ding Baoqin 86-13906276368

Fax: 86-513-88400998

E_ mail: jszk@vip.163.com

Address: No. 29 Xingdian West Road, Baidian Town, Hai'an City, Jiangsu Province