Automobile bulk machine

Keywords:

Heavy machinery | Power station auxiliary equipment | Engineering general contracting | Mining machinery | Environmental protection equipment

Category:

Service hotline:

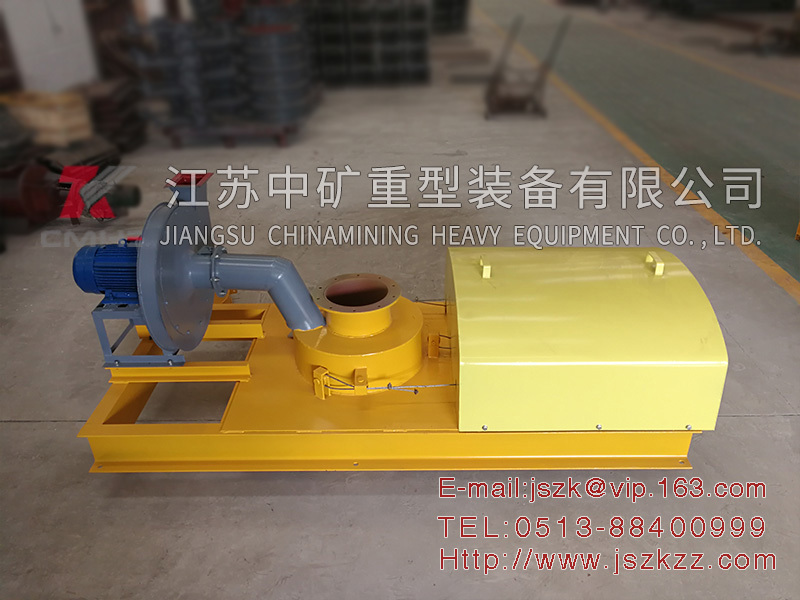

Automobile bulk machine

Bulk loader for truck is developed by Jiangsu ChinaMining based on both domestic and international successful experiences. It is suitable for industries such as electricity, building materials, chemical industry and grain to load dry powder and granular materials into vehicles and ships. SZ type automotive bulk loader series products passed the provincial new product appraisal in 1993, and were awarded the Provincial New Product Golden Bull Award and the Municipal New Product Golden Eagle Award in 1994. The technical indicators have reached the level of similar products. The SZ truck bulk loader has the characteristics of automatic control, large unloading capacity, no dust pollution, reliable indication of full material, simple structure and low cost. Bulk loaders for truck are mainly used in thermal power plants for loading and loading under dry dust collectors, ash hoppers or ash storage warehouses, and slag depots. The automobile bulk machine can be interlocked with the feeding facilities under the material warehouse for operation. After the material truck is full, it automatically stops loading, achieving automation of the loading and unloading process. The loading efficiency is high and dust pollution is low. It is ideal equipment for loading bulk powder and granular materials into trucks and ships. After years of operation, it has been proven that Jiangsu ChinaMining Automobile Bulk Machinery is an innovative product that is highly welcomed by users.

In response to the problems found in the use of similar products both domestically and internationally, our company has made the following improvements

The inner telescopic feeding tube has been changed to a steel structure, with a lifespan 8 to 10 times longer than that of a cloth bag, reducing the feeding resistance and a production capacity of up to 200 tons/hour.

The material level controller has been changed from the original micro pressure controller to rotary resistance level controller, overcoming the frequent drawback of affecting the control signal due to blockage.

Composition and Application of Bulk Loader for truck

The bulk loader for truck mainly consists of an internal and external expansion joint, an electric drive mechanism, an induced draft fan, a pressure level gauge and a base to form a complete production and loading system.

Automobile bulk machines are widely used as supporting dust collection and recovery devices for various types of smoke and dust collectors, bag filters, high-voltage electrostatic precipitators and other discharge port auxiliary devices. The scope of application and enterprise fields are very wide, such as supporting dust recovery and treatment of smoke and dust removal equipment in various enterprises including large, medium, and small power plants, thermal power plants, cement plants, coal mines, chemical product factories, liquor factories, paper mills, corn development and production enterprises. It is a new generation of packaging machinery developed and designed based on the characteristics of advanced control technology from foreign models and the national conditions of China.

Bulk loader for truck is mainly used in thermal power plants for loading and loading under dry dust collectors, ash hoppers or ash storage warehouses, and slag depots. The automobile bulk machine can be interlocked with the feeding facilities under the material warehouse for operation. After the material truck is full, it automatically stops loading, achieving automatic control. The loading efficiency is high, and dust pollution is low. It is ideal equipment for loading bulk powder and granular materials into trucks and ships.

Working principle of automobile bulk loader。

After the transport vehicle is in place, a semi-automatic control mechanism is used to lower the bulk head. When the bulk head is tightly connected to the upper part of the vehicle's ash inlet, the automatic control mechanism is then activated. Automatically turn on the fan, then turn on the upper feeder, and start to unload materials into the vehicle. When the material tank is full, the level gauge senses and sends a signal, and the corresponding electrical and pneumatic control system automatically turns off the upper feeder. For a period of time (usually 4-6 seconds), the vacuum fan is automatically turned off, and the bulk head is automatically lifted to complete the unloading process. The feeder and vacuum fan are mutually locked during the loading and unloading processes. Once the previous action is executed, the latter action cannot be opened or closed. To disrupt the above sequence, the interlock has to be released.

Technical parameters of automobile bulk loader

1600mm,8m/min;

The expansion and contraction distance of the loading head is 1600mm, and the extension and descent speed is 8m/min.

Hoisting speed of the winch is 8m/min with power of 05.KWJ and voltage of 380V.;

Technical parameters of the pressure controller in the material level indicator mechanism; Operating pressure 250-5000Pa, rated voltage 220V; Rated current 3A, suitable medium: clean gas; Pressure 0.01MPa, fan technical parameters pressure 220V, power 350V;

When the floor slab is thin, the bolt holes for the corner bolts should be directly drilled as shown in the figure. The bolt GB5780-86M12X1L=40+the thickness of the floor slab;

Equipped with a dust collector, with a dust collection air volume of 40m3/min

The electric control box will be discussed separately when ordering.

More Products

Product Consultation

Website

Service hotline

Business Department:

Zhou Baohua 86-13906278080

Technical support:

Ding Baoqin 86-13906276368

Fax: 86-513-88400998

E_ mail: jszk@vip.163.com

Address: No. 29 Xingdian West Road, Baidian Town, Hai'an City, Jiangsu Province