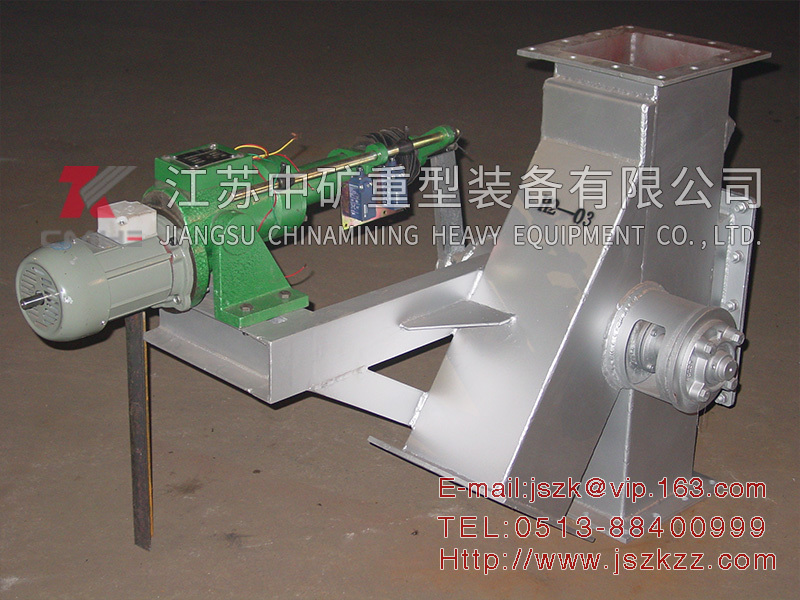

SK two-way delivery valve

Keywords:

Heavy machinery | Power station auxiliary equipment | Engineering general contracting | Mining machinery | Environmental protection equipment

Category:

Service hotline:

SK two-way delivery valve

I. Purpose

SK dual-channel conveying valve is generally suitable for industries such as building materials, metallurgy, mining, petrochemicals, power and light industry. It is used in high-pressure pneumatic conveying of cement, cement raw materials, limestone, coal powder and other powdery substances in pipeline systems. It is used for conveying and reversing and is generally installed at the bifurcation of pipelines.

II. Structural characteristics

The internal reversing of SK dual-channel conveying valve adopts a rotating valve disc, which is controlled by a pressure regulating device to match the sealing surface. The valve disc adopts a knife-shaped shape to cut off attachments on the sealing surface during movement and ensure sealing performance. The dual-channel conveying valve structure of Nantong ChinaMining is complete with flexible and reliable direction change, good air tightness and smooth conveying channels without blockages, ensuring smooth fluid flow. S is a worm gear transmission type, D is an electric transmission type, and Y is an electro-hydraulic transmission type

III. Specification

SK dual-channel conveying valve have 8 specifications, among which valves with a diameter of 76mm (3") to 152.4 (6") matching the inner diameter of pipes of the 40 wall series, and valves with a diameter of 203mm (8") to 356mm (14") matching the inner diameter of pipes of the 30 wall thickness series. The SK valve operating rod has left-mounted and right-mounted types and manual and electric operations, with temperatures up to 204℃ (400℉).

IV. Working principle

SK dual-channel conveying valve is mainly composed of left and right valve bodies, rotating valve discs, adjustment devices, sealing surfaces and positioning camshafts. Manually operate the hand wheel to drive the worm gear with a driving lever, and the valve disc moves together. The valve body is in a straight or branch position, and the dial provides feedback on the valve disc position; When the driving device receives a command to act, it drives the control lever and valve disc to act together, causing the valve body to be in a straight or branch position. At the same time, a position signal is fed back. When the positioning cam mechanism reaches the position of the valve disc, the electrical switch is activated, and the feedback signal is given.

V. Model preparation instructions

SKK-150 S worm gear drive, D electric, Y electro-hydraulic

VI. Performance parameter

|

Working pressure |

Temperature |

Applicable medium |

|

0.5MPa |

≤200℃ |

Powder and particle materials such as coal powder, raw materials, cement, etc |

More Products

Product Consultation

Website

Service hotline

Business Department:

Zhou Baohua 86-13906278080

Technical support:

Ding Baoqin 86-13906276368

Fax: 86-513-88400998

E_ mail: jszk@vip.163.com

Address: No. 29 Xingdian West Road, Baidian Town, Hai'an City, Jiangsu Province