Light plate conveyor

Keywords:

Heavy machinery | Power station auxiliary equipment | Engineering general contracting | Mining machinery | Environmental protection equipment

Category:

Service hotline:

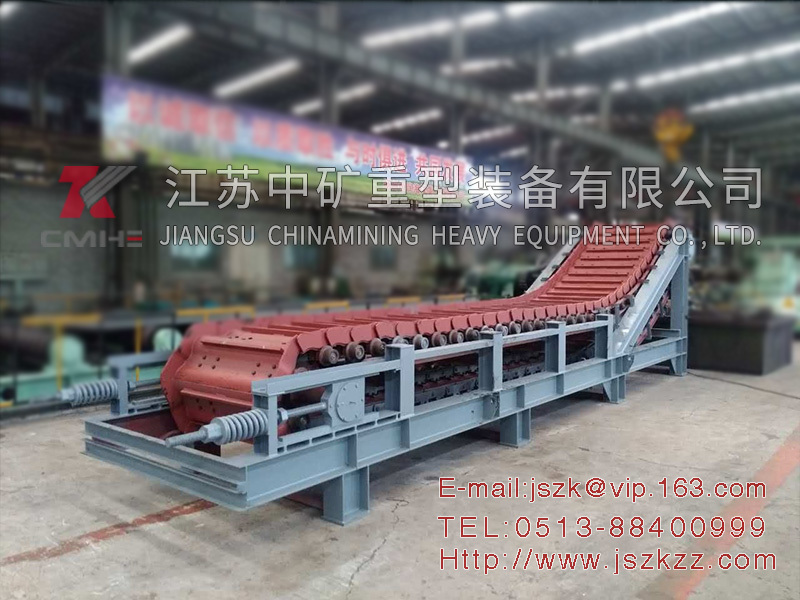

Light plate conveyor

Product Introduction

BZ light plate conveyor is the auxiliary equipment of transportation machinery, which is used as a silo for continuous and uniform feeding of primary crusher in the crushing and grading workshop of large concentrator and cement, building materials and other departments, and can also be used for short-distance conveying of materials with large particle size and specific gravity. It can be installed horizontally or obliquely, with an inclination angle of 12 degrees.

Features:

• The drive chain adopts the standard dry track chain produced by professional manufacturers, which does not require lubrication and is easy to install and maintain.

• All key connection parts are connected by expansion sleeve and locking plate, which does not damage the shaft diameter, reduces stress concentration, and is convenient for disassembly and assembly.

•The groove plate is a stamping and welding structure, the groove plate overlaps with each other, there is no leakage during work, and the groove plate is strengthened up and down, which has a greater bearing capacity.

• The driving device adopts a suspension single-point floating support mode, and the tooth warp meshing is not affected by the foundation accuracy, which can minimize the radial installation size of the plate feeder.

Type, basic parameters and dimensions

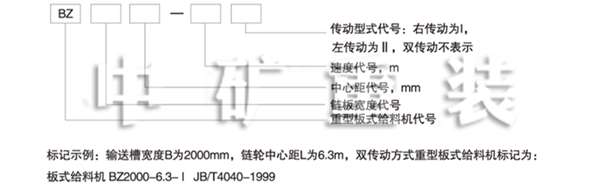

•version

Light-duty plate conveyors are divided according to the transmission mode

a) Right transmission: The transmission device is on the right side of the material running direction

b) Left transmission: The transmission device is on the left side of the material running direction

It is divided according to the way the feeding speed changes

a) Fixed speed type

b) Speed regulation type

Technical Specifications & Dimensions

|

Model |

Width of Groove Plate (mm) (mm ) |

Head and tail axle center distance(mm) |

velocity (m/s) |

Feed size(mm) |

Processing capacity (t/h) |

Motor power(kw) |

Dimensions(mm) |

remark |

|

BZ160-9 |

1600 |

9000 |

0.01-0.07 |

≤1000 |

27-270 |

30 |

11250x4153x2890 |

|

|

BZ180-8 |

1800 |

8000 |

0.01-0.07 |

≤1000 |

≤500 |

37 |

10250x4153x2890 |

|

|

BZ180-8.75 |

1800 |

8750 |

0.01-0.07 |

≤1000 |

≤500 |

37 |

11050x4553x2890 |

|

|

BZ180-9 |

1800 |

9000 |

0.01-0.07 |

≤1000 |

≤500 |

37 |

11250x4553x2890 |

|

|

BZ180-9.8 |

1800 |

9800 |

0.01-0.07 |

≤1000 |

≤500 |

37 |

12000x4553x2890 |

|

|

BZ180-10 |

1800 |

10000 |

0.01-0.07 |

≤1000 |

≤500 |

37 |

12200x4553x2890 |

|

|

BZ200-9.8 |

2000 |

9800 |

0.01-0.07 |

≤1000 |

≤500 |

37 |

12000x4553x2890 |

|

|

BZ220-10 |

2200 |

10000 |

0.01-0.07 |

≤1200 |

≤700 |

45 |

12000x4753x2890 |

|

|

BZ230-10 |

2300 |

10000 |

0.01-0.07 |

≤1500 |

≤800 |

45 |

12000x4853x2890 |

|

|

BZ240-10 |

2400 |

10000 |

0.02-0.06 |

≤1600 |

≤850 |

2x37 |

12000x4953x2890 |

|

|

BZ250-11.5 |

2500 |

11500 |

0.01-0.07 |

≤1800 |

550-900 |

2x45 |

12000x5053x2890 |

|

Note:

1. The center distance is the distance between the centerline of the drive sprocket and the axis line of the tensioned sprocket.

2. The width of the chain plate is the inner width of the bottom of the chain plate.

Pay attention to the items

1. The allowable deviation of the center distance of the sprocket is in one chain pitch

2. The feeding speed of the conveyor shall be selected according to the following series, and its deviation shall not exceed ±10%

|

velocity code name |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

T |

|

velocity m/s |

0.02 |

0.025 |

0.03 |

0.04 |

0.05 |

0.06 |

0.08 |

0.10 |

0.12 |

0.16 |

0.20 |

0.02-0.2 or 0.05-0.16 |

|

Note: T is the speed code of the speed regulation, where 0.05-0.16 is suitable |

For BZ3150 |

|||||||||||

Model mark

More Products

Product Consultation

Website

Service hotline

Business Department:

Zhou Baohua 86-13906278080

Technical support:

Ding Baoqin 86-13906276368

Fax: 86-513-88400998

E_ mail: jszk@vip.163.com

Address: No. 29 Xingdian West Road, Baidian Town, Hai'an City, Jiangsu Province