Medium plate conveyor

Keywords:

Heavy machinery | Power station auxiliary equipment | Engineering general contracting | Mining machinery | Environmental protection equipment

Category:

Service hotline:

Medium plate conveyor

Product introduction

Medium-sized plate feeder is an intermittent feeding machine, suitable for short distance transportation of block materials with particle sizes of less than 400mm. It is widely used in mining, mineral processing plant, chemical, cement, building materials and other industries for uniform intermittent feeding from storage silos to crushing and transportation machinery. It can be installed horizontally or tilted, with an upward tilt angle of 20 degrees, and is generally suitable for materials with a loose density less than 12400kg/m3 and a temperature below 400 degrees Celsius.

Product features

The tail device is designed to be suitable for rainy and humid areas, and will not cause chain tooth jumping due to the accumulation of sticky materials at the tail, which will affect production.

The traction chain and the load-bearing chain are separated, reducing dynamic load and improving service life. The conveyor chain is designed and manufactured according to IS01977/1-1976, with excellent material selection, reliable quality and good interchangeability.

The sprocket of the head device consists of three flapper teeth, which can be replaced without disassembling the chain and is easy to maintain. The odd and even teeth of the sprocket are transmitted separately which can double the service life. The surface of the sprocket is hardened and has a long service life, in accordance with the regulations of 1977/II-1974.

All machines are equipped with rolling bearing support structures, which have good sealing and lubrication performance, low running resistance, and are easy to maintain, thus possessing the characteristics of energy conservation and simple maintenance.

The width parameters of this machine are designed according to the standards of F.L.SMLDTH (Denmark) and AUMUND (Germany) companies.

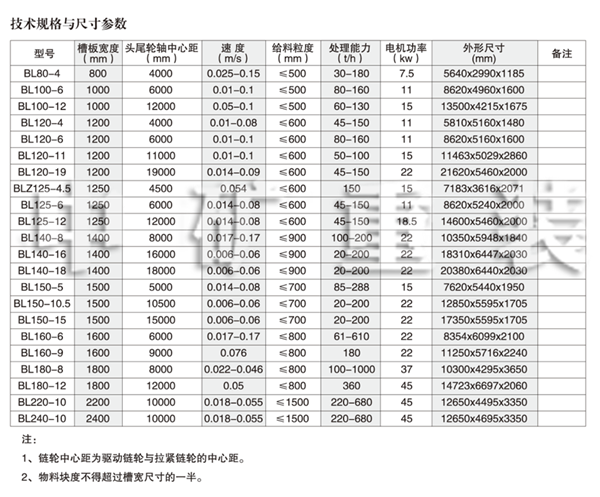

Model, basic parameters and dimensions

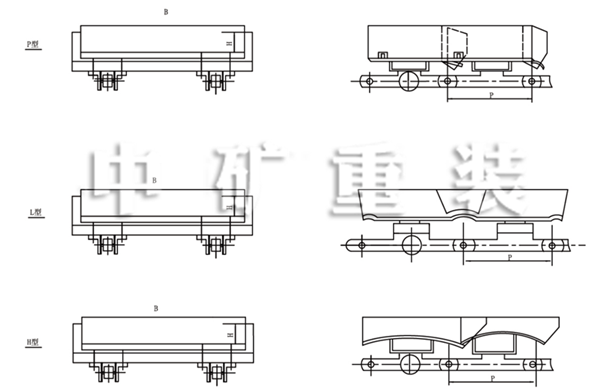

The medium-sized plate feeder is divided into three types according to the conveying groove structure that carries the materials.

The longitudinal section of the P-type conveying trough bearing plate is a flat plate type, suitable for conveying block materials along a horizontal or inclined angle of less than or equal to 15°.

The longitudinal section of the L-shaped conveying trough bearing plate is wavy, suitable for conveying block and granular materials along a horizontal or inclined angle of less than or equal to 25°.

The longitudinal section of the H-type conveyor trough bearing plate is circular arc shape, suitable for conveying wet and viscous materials along a horizontal or inclined angle of less than or equal to 25°.

The allowable deviation of sprocket center distance ≤ one chain pitch.

0.01; 0.02; 0.03; 0.04; 0.05; 0.063; 0.08; 0.10; 0.125; 0.16; 0.20; 0.25m/s

The feeding speed of the feeder shall be selected according to the following series, and the deviation shall not exceed ± 10%

0.01; 0.02; 0.03; 0.04; 0.05; 0.063; 0.08; 0.10; 0.125; 0.16; 0.20; 0.25m/s

When the feeding speed of the feeder needs to be adjusted, speed regulating motors are used. Generally, Y-series asynchronous motors are used.

The traction chain adopts sleeve roller conveyor chain, with a pitch series of 200; 250; 315; 400mm

The sprocket adopts the design rule of conveyor chain sprocket of sleeve roller, and the number of teeth is selected from the following numbers: 6; 8; 9; 10.

The transmission mode of the feeder is divided into three types: right transmission, left transmission, and bilateral transmission.

The transmission device is right transmission on the right side of the material running direction, and vice versa, it is left transmission. Mark with I and II respectively. Bilateral transmission is not marked.

According to the width of the conveying trough, there are two forms of support for the trough body. When the width of the conveying groove is less than or equal to 1600mm, the groove body is supported by the rollers fixed at both ends of the conveying groove, and the roller runs along the upper and lower guide rails of the bracket. When the width of the conveying groove is greater than 1600mm, the groove body is supported by rollers fixed on the frame.

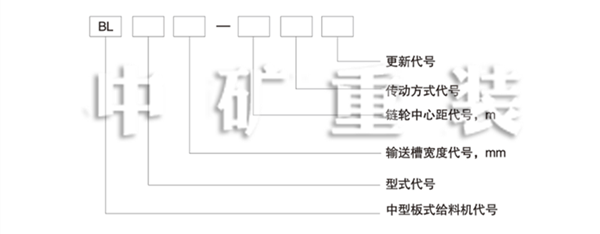

Model markings

Example of marking: The width B of the conveying groove is 1600mm, in the form of L-shape, and the center distance L of the sprocket is 15m. The marking for universal fixed medium plate feeder with right transmission is: Plate feeder BL1600-15 I JB/T4255-1999.

More Products

Product Consultation

Website

Service hotline

Business Department:

Zhou Baohua 86-13906278080

Technical support:

Ding Baoqin 86-13906276368

Fax: 86-513-88400998

E_ mail: jszk@vip.163.com

Address: No. 29 Xingdian West Road, Baidian Town, Hai'an City, Jiangsu Province