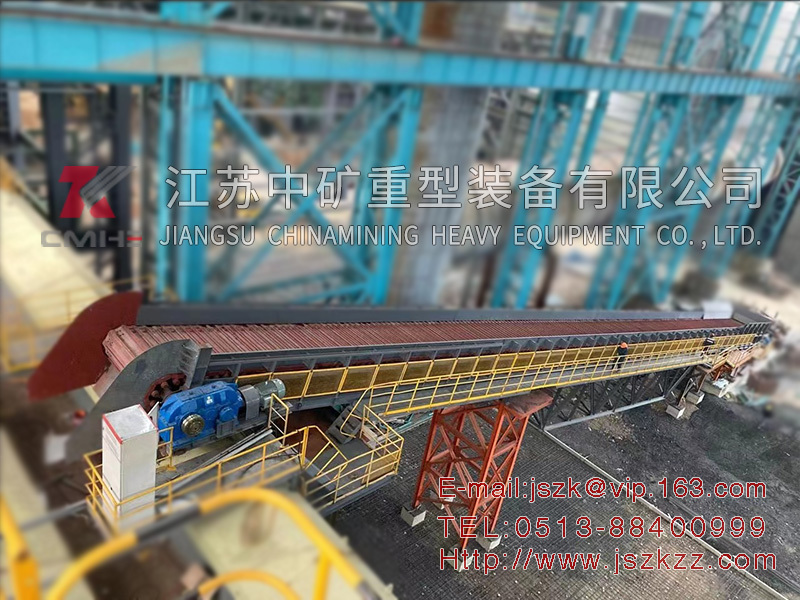

Scrap steel chain plate conveyor

Keywords:

Heavy machinery | Power station auxiliary equipment | Engineering general contracting | Mining machinery | Environmental protection equipment

Category:

Service hotline:

Scrap steel chain plate conveyor

Product Introduction

The traditional electric arc furnace generally adopts the method of charging the top of the basket, and the furnace cover needs to be opened 2-3 times for each furnace of steel, and the scrap steel is added to the basket, which has large heat loss, high smelting cost, large smoke and dust overflow, and poor working environment. At present, the production capacity of China's iron and steel industry has been adjusted, and a large number of intermediate frequency furnace steelmaking enterprises have transformed into electric arc furnace steelmaking. There was an urgent need for an electric arc furnace charging unit capable of continuously conveying scrap.

The chain scrap conveyor is a conveying equipment that is composed of a series of metal chains that are supported on roller chains and overlapped with each other to form a continuously moving working face to carry bulk solid materials. And it can withstand a certain impact force. At the same time, due to the large traction force of the traction chain of the chain conveyor, the scrap steel chain conveyor has the characteristics of large carrying capacity, high conveying capacity, small running resistance, long conveying distance, convenient installation and maintenance, and long service life. It can not only convey horizontally, but also at an inclined level; It can be multi-point feeding, and the equipment process layout is flexible.

Features:

1. The walking conveyor can continuously and evenly add scrap steel to the electric arc furnace.

2. Increase the height of scrap steel in the conveying process and use it in a lower plant.

3. The conveying speed is controllable, which is synchronized with the smelting speed of the electric furnace.

4. There is no need to open the furnace cover, and the scrap steel is continuously added to the electric arc furnace to reduce the production cost.

5. Shorten the production cycle and improve productivity.

6. Good dust-proof effect and reduce environmental pollution.

Technical performance

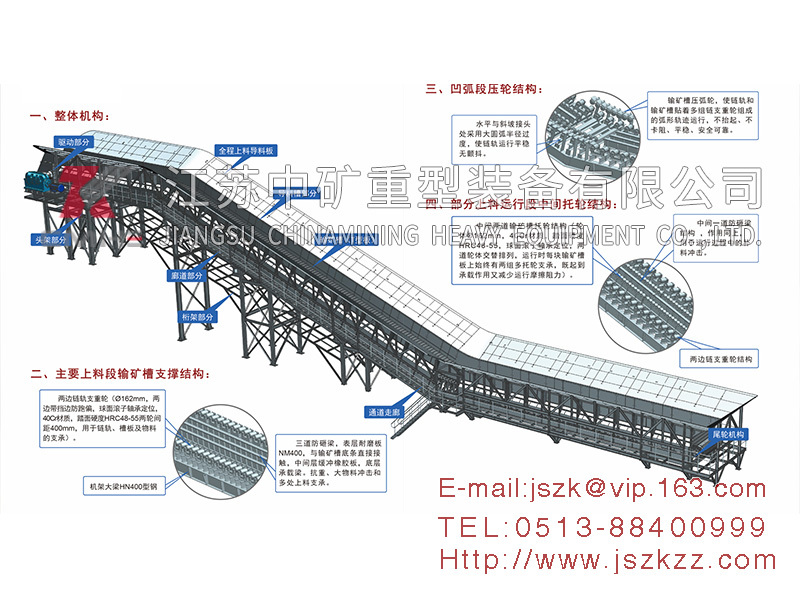

1. The roller type scrap heavy plate conveyor can adapt to harsh climates such as severe cold, and can also continuously and normally convey materials.

2. The transmission mechanism is reliable, which can ensure the long-term trouble-free operation of the switchboard.

3. It adopts a variable frequency speed regulating motor, and has the characteristics of large driving torque, wide speed regulation range and high control accuracy, which can maintain a constant driving torque during low-speed operation to ensure stable operation at low speed. The running speed of the chain conveying trough can be adjusted by adjusting the motor speed, so as to control the size of the material conveying volume.

4. The starting mode is: direct start with inverter.

5. Chain rollers, intermediate supporting rollers and rails effectively strengthen the support chain plate, more powerful resistance to the impact of materials and running resistance, the equipment can withstand the transportation of large heavy materials, the supporting roller is evenly stressed, and the service life is long.

6. The T-shaped structure of the chain plate with torsion tendons has high strength, no deformation, and good interchangeability.

7. The conveyor chain adopts standard rail chain, which is durable and easy to replace. The 35MnBM chain rail is impact resistant, has a large breaking load, runs smoothly and works reliably.

8. There is an arc-shaped connecting plate lap at the connection between the main chain plates, and no material leaks from the gap of the chain plate.

9. The flat design of the conveying trough is closely combined with the side plate, and there is no jamming and no leakage.

10. The frame is a frame structure with high-strength I-beam as the skeleton, which is stable and solid, and has strong bearing capacity.

11. All steel structures that need to be dismantled and transported shall be pre-assembled in the factory before shipment, and if they are connected by bolts, they shall be connected by bolts with high strength.

More Products

Product Consultation

Website

Service hotline

Business Department:

Zhou Baohua 86-13906278080

Technical support:

Ding Baoqin 86-13906276368

Fax: 86-513-88400998

E_ mail: jszk@vip.163.com

Address: No. 29 Xingdian West Road, Baidian Town, Hai'an City, Jiangsu Province